The Perfect Wedding Gift: Restoring a 1964 E-Type Jaguar

How did the car come to us?

The restoration of this particular Jaguar E-Type started with a wedding. A 1964 series one finished in carmen red with an original 3.8 XK engine, which the young gentleman brought to us for a nut and bolt restoration. He treasured it as a part of his joyous marriage celebration, and thus became a much-loved family car. So it was important to him that it was brought back to its full factory spec (with a few modern tweaks) and could be loved and enjoyed for many years by himself and his surrounding family.

Pictured: How the car arrived.

Our role at P&K Thornton is to realise this customer's dream of getting his E-Type classic Jag back in better than perfect condition with the customer's specific needs. He wanted two particular systems upgraded: improved brakes and a more efficient cooling system. At P&K Thornton, we don't just restore cars for customers. We delve deeper and get individual requirements for every customer. We work with customers to realise a car that's personal to them. That could be updated brakes or an electronic ignition system for easier starting. It could be your daily driver, and you need the reliability of a modern car. Whatever you choose, if you want your dream car, we'll custom-build that for you.

We spoke with the owner regarding his E-Type. He wanted modern upgrades like front brakes with front cast aluminium callipers, a rebuilt cooling system, and a reliable ignition. We sometimes fit aluminium bonnets as they’re lighter and won't rust. However, this customer wanted to keep the original bonnet to keep it authentic.

Nut and Bolt Restoration

Firstly, we needed to completely strip the paint back to assess the body's condition. This was carefully carried out using glass media blasting, which is a lengthy process due to avoiding heat damage to the metal. If you're in the business of Jaguar E-Types, it's known that rust is prone to the sills, rear wings, and body areas. And, well, this particular Jag was very, very rusty. We noticed that the floors were bonded in with silicone and riveted. Even the windscreen pillars were stuffed with old newspaper (yes, really!) held up by what could only be described as “pure magic”. Many of the car's panels were replaced with overly thick grade steel panels that must be addressed. We see many cheap repairs from the 1990s and earlier when E-Types weren't worth as much. It's a sad state of affairs for classic car restorers. And this Jaguar E-Type was in quite a dangerous condition that must be addressed with an entire bottom-to-top in-depth rebuild and restoration.

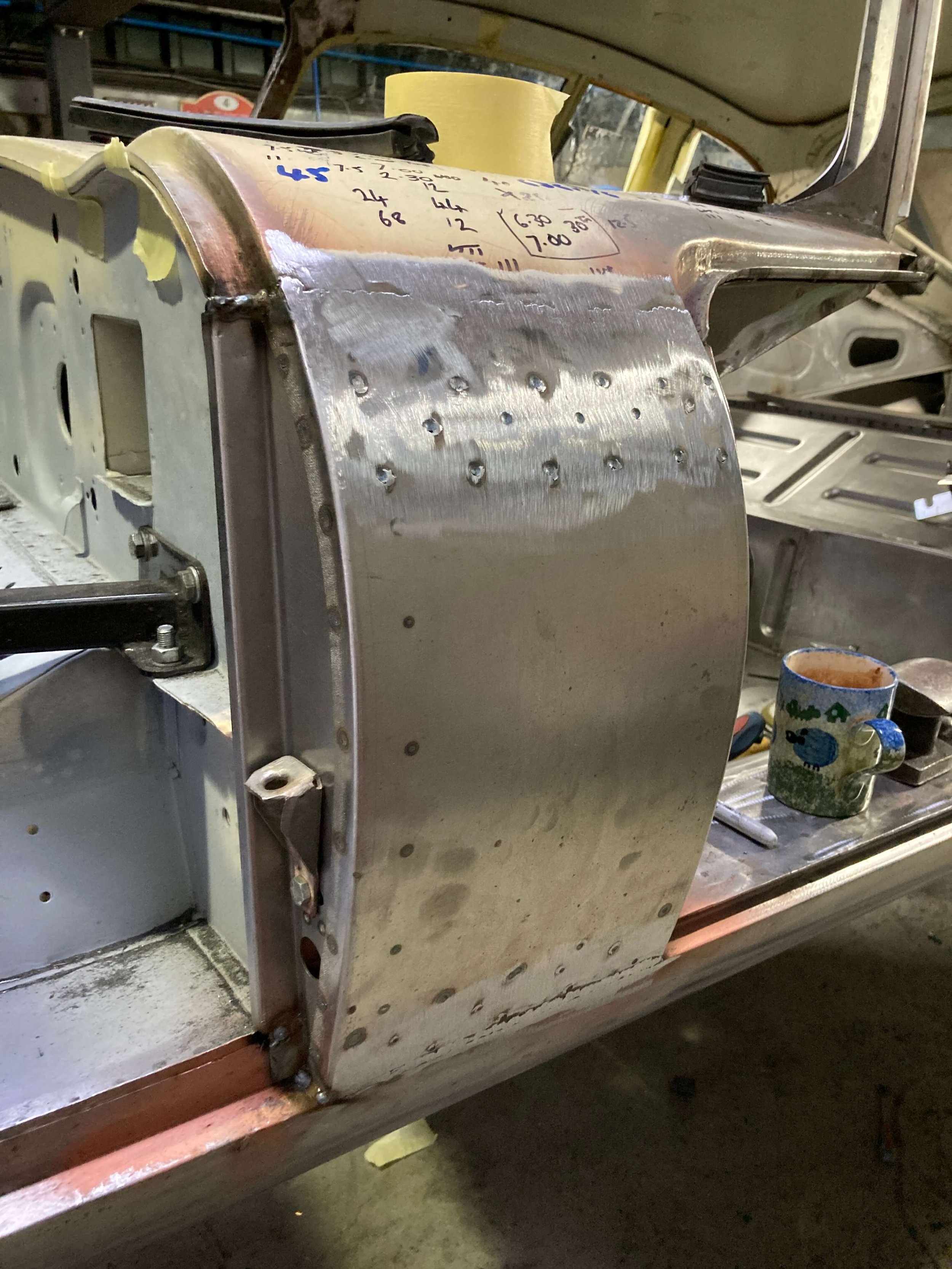

The car needed a complete metal rebuild throughout, and it's here where our experience is critical to get that perfect finish. We’ll take each panel, analyse it thoroughly, and assess whether it’s restored or replaced. Our panel beaters have complete authority over panel condition and are maestros with MIG/TIG welders due to thousands of hours working and specialising in E-Type Jaguar body panels. So we've got this down to a fine art. Plus, focusing on one make and model of one car allowed us to excel in knowing every single part, from the entire body curves to the most minor panel. This is why our customers are overjoyed with their cars when we return them. Not only did we reconstruct the panels, but we also fitted the car with new ones where required. We also added structural reinforcements underneath the sills to reduce torsion, plus bulkhead sides and rear wings. In the 60s, these construction safety concerns weren't on the Jaguar designer's horizon. But we need to be more vigilant these days, making our project cars safer without losing that Jaguar E-Type vintage ambience.

Getting the body panels prepared correctly is vital to painting the Jaguar. And this one was no exception. The customer wanted the original colour. So it was critical that the panels were precisely aligned and that the body symmetry was achieved. When we start a restoration, we analyse every piece as it comes off. Whether it needs replacing or restoring. We then create a blueprint for every car we work with on how we approach the project. It's a labour of love for us, so this intricate process is all part of how we work. We then look at the internal workings. The engine, suspension, interior, electrics, and IRS are all considered, even a fresh zinc finish for all original nuts and bolts. Everything is noticed.

Pictured: A progress shot of the bodywork.

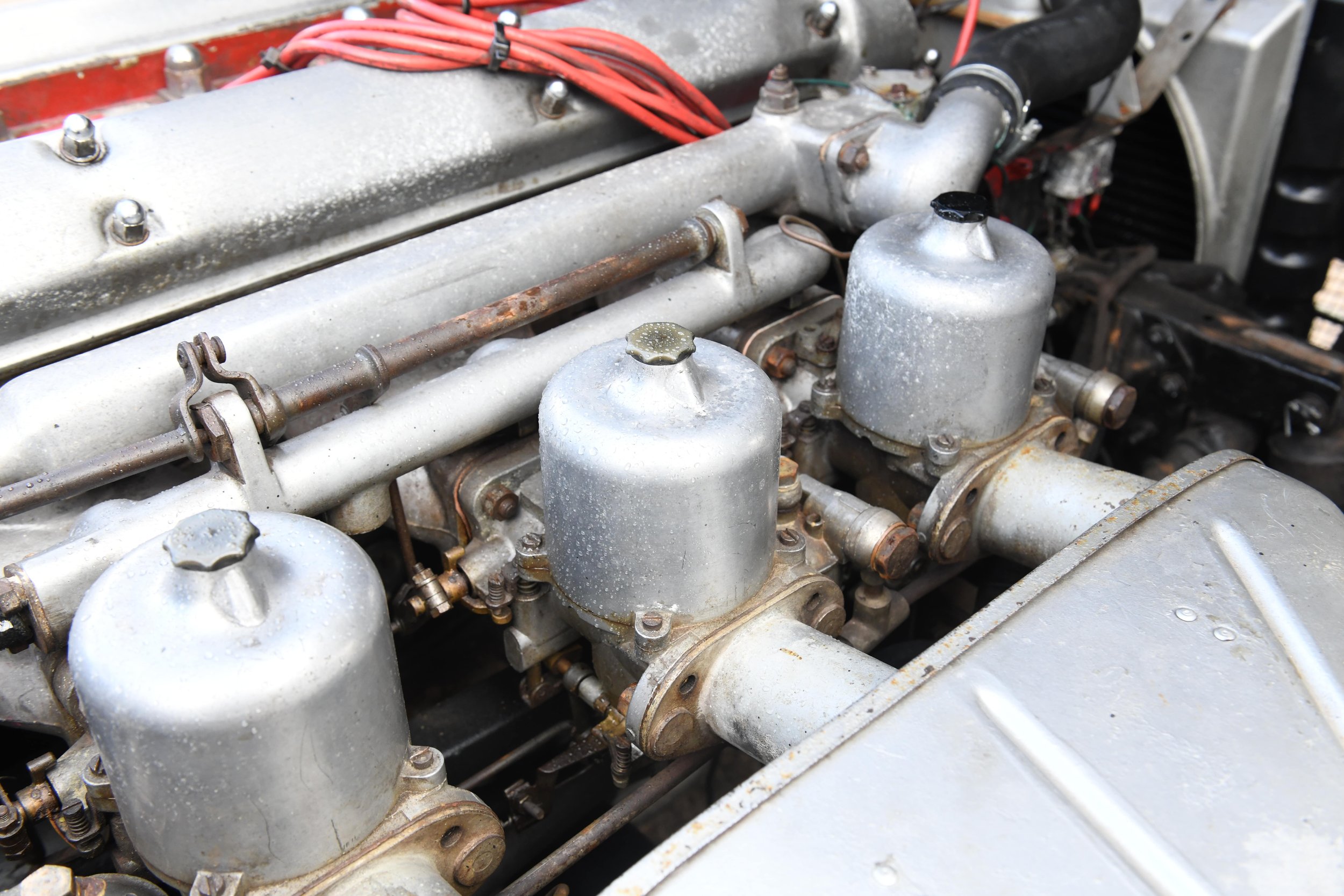

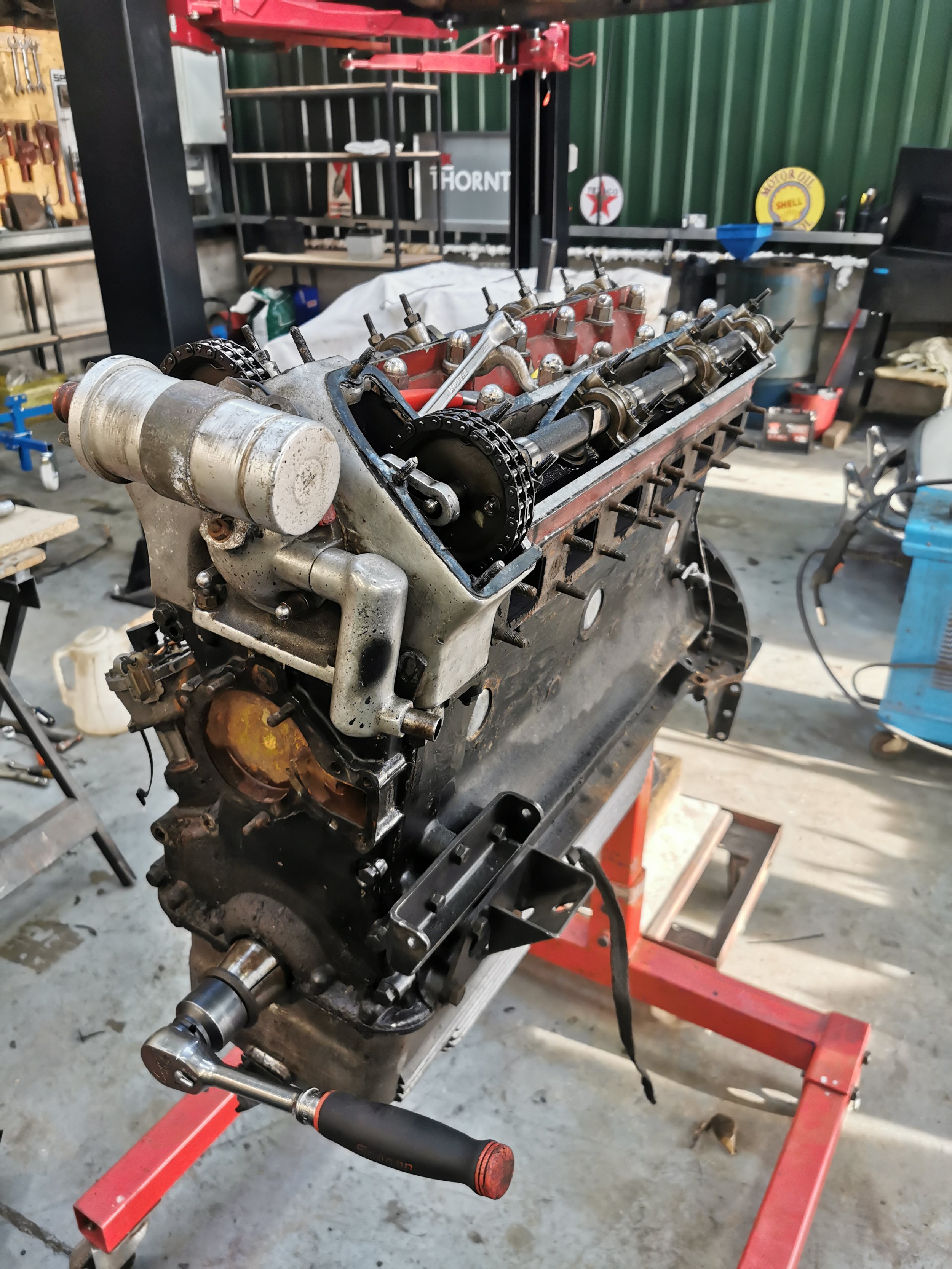

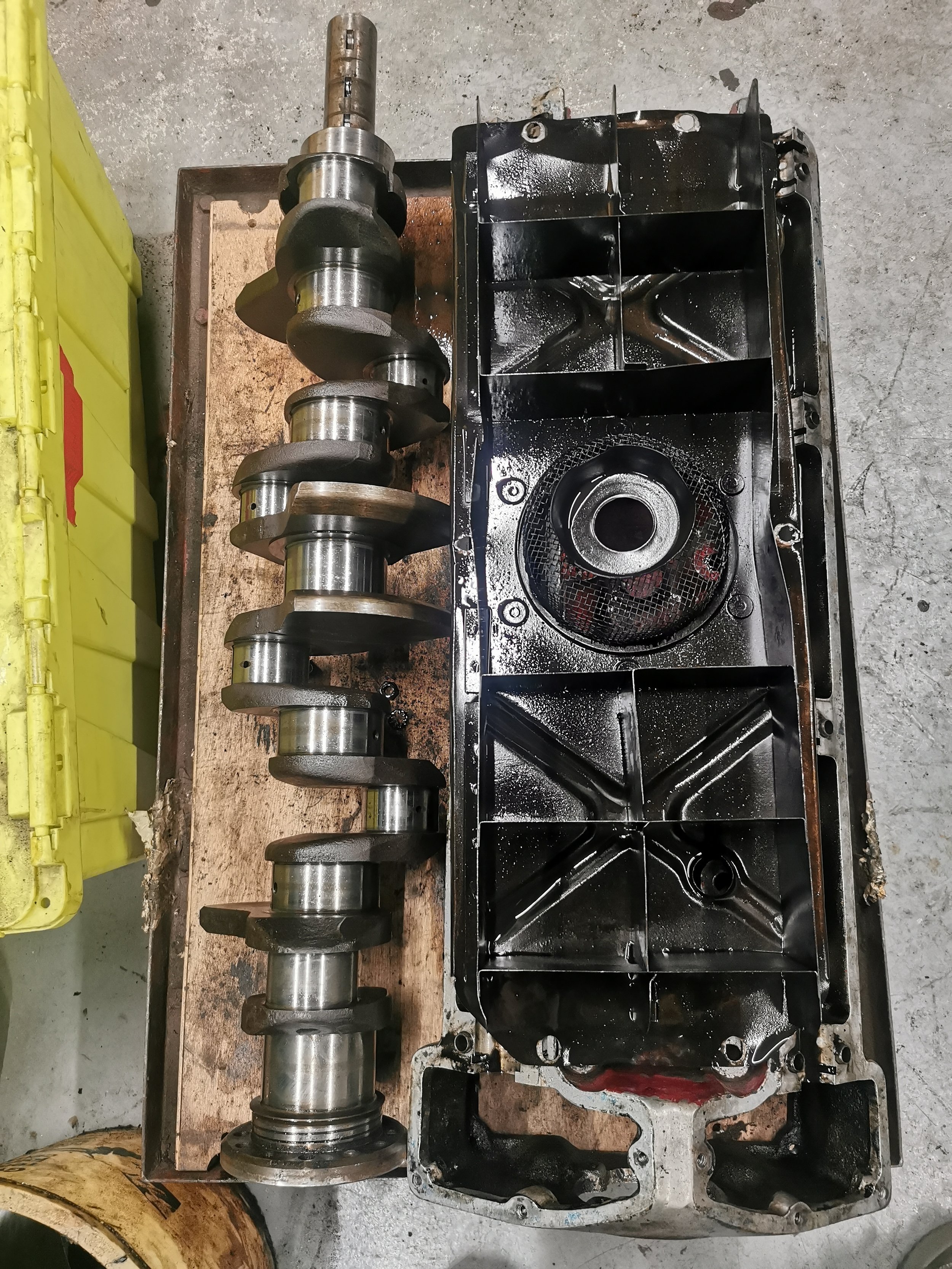

Pictured: The gearbox after being removed.

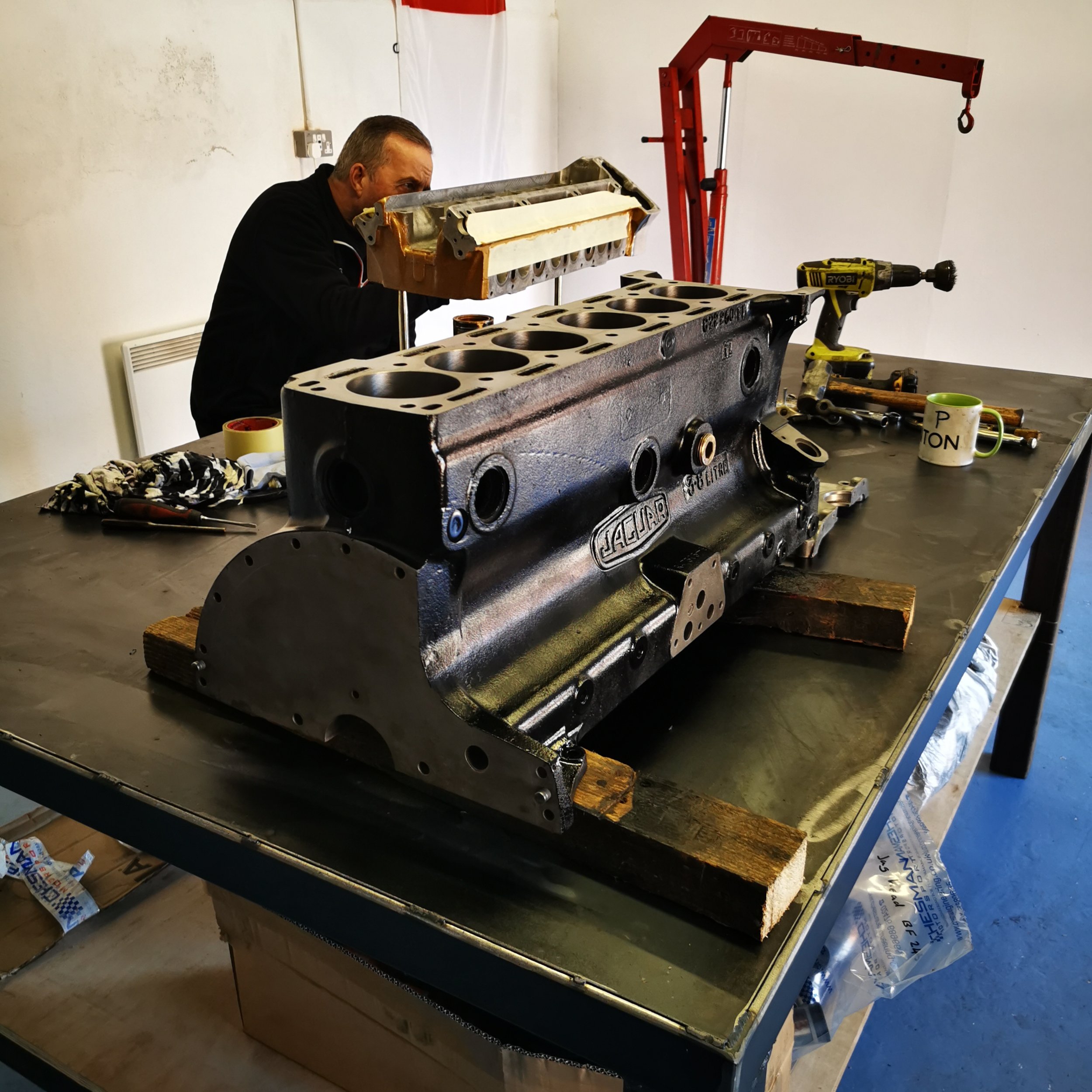

The XK engine and gearbox were stripped back and rebuilt from scratch, with every single component removed, inspected, and documented. We replace some components with performance upgrades, depending on the customer's specifications. We took every engine's internal workings, like the carburettors, crankshaft, and pistons, pulled them back from the engine block, rebuilt them from the bottom up, and added aftermarket upgrades to increase performance. Our XK engine rebuilds are detailed, including vapour cleaning components, balancing, machining and polishing. Our classic car technicians leave no detail out, ensuring that all the engine parts work perfectly. Once the engine is reassembled, one of our techniques is to place a pound coin on its side while running to check the stability and balance. If it doesn’t fall off after a minute, we’re happy. We changed the ignition system to electric for easier starting. We brought in an aluminium radiator, header tank, and an electric fan for an improved overall cooling system to cope with the hot British summer weather. We also installed a quick bleed system on the IRS and a top access panel for hand brake mechanism adjustment. Finally, we reupholstered the trim, installed the glass, and fit the freshly chromed parts. These finer restoration details make us stand out as a company.

Pictured. The restored engine.

Pictured: Restored interior of the E-type.

To keep restorations in our control, we like to do everything under one roof and rarely send parts away for repair or restoration. And when we do, like when we need bumpers re-chroming, we only work with the leading classic car specialists and engineers we trust. So most of the restoration is with us, all thanks to our years and person-hours of experience. Once it's in a running state, we'll take the cars out and thoroughly put them through their paces on the roads. Checking the XK engine is purring, the steering is responsive, and the suspension is balanced. One of our techniques to check the stability of the Jaguar’s engine is to place a pound coin on its side on it, and if it doesn't vibrate off in a minute, we’re happy that the XK engine is balanced. This particular 64 E-Type Jag went out several times and was road tested thoroughly in all weather conditions. Sun, rain, wind, and even snow. It’s an excellent way to find any mechanical niggles that may need adjusting. It's all in the detail at P&K Thornton.

We won't scrimp on time, and this particular project took a lengthy 18 months and 5000 person-hours to bring this Jaguar E-Type back to its second life. All our projects vary in length, and we'll give you a completely honest opinion on the amount of time it'll take. We have a complete open-door policy, and you're always welcome to come and chat with us about how your project is progressing.

Why let us Restore your E-Type?

At P&K Thornton, it isn't just about taking your car apart and putting it back together. Ciprian's eye for detail and bespoke restoration experience allows P&K Thornton Restorations to offer more than just rebuilding your beloved car. It's their commitment to preserving automobile history and allowing the world to experience the love of E-Types, seeing the cars in their original guise.

Pictured: The restored E-type with its Engine on show.

His family of dedicated classic car technicians and panel beaters have created a world where you can take pride and joy and give it a second life. Every project, every car, and every part is maliciously worked on. And when it's finished, it's like it rolled off the production line right at its birth (sometimes with a few extras!). At every stage of the restoration, we'll test whether every part is working together in unison before they hand it back to you. We’ll prepare your car for many more years of love and joy it deserves. The curves, the sound, the smell, the feel, and the drive, are everything we want to achieve when we commit ourselves to a restoration–celebrating and cherishing the legacy of the iconic E-Type Jaguar with unbridled adoration and devotion.

0115 9262266 or info@thorntonrestorations.com